Blasting Nozzle

Blasting Nozzle Specification

- Diameter

- 2 mm to 12 mm (bore size, as per requirement)

- Shape

- Cylindrical

- Product Type

- Blasting Nozzle

- General Use

- Abrasive blasting and surface cleaning applications

- Material

- Tungsten carbide with aluminum or steel jacket

- Type

- Venturi or Straight bore

- Capacity

- Standard flow, varies with nozzle size

- Weight (kg)

- 0.2 0.8 kg (depending on model)

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual operation

- Surface Treatment

- Anti-corrosion finish

- QC System

- Standard industrial quality control

- Tolerance

- 0.05 mm

- Drawing

- Available on request

- Dimension (L*W*H)

- Varies by model, typically 100-200 mm length

- Feature

- High wear resistance, long service life, uniform abrasive flow

- Color

- Grey (body), black tip or as per model

Blasting Nozzle Trade Information

- Minimum Order Quantity

- 1-2 Kit

- Main Domestic Market

- All India

About Blasting Nozzle

Unmatched Performance & Versatile Application

Our blasting nozzle stands out with high wear resistance, extended service life up to 400 hours, and uniform abrasive flow. It is compatible with multiple abrasives, making it ideal for industrial sandblasting, paint stripping, rust removal, and surface cleaning. The nozzle's anti-corrosion finish and precise tolerances ensure maximum efficiency for distributors, manufacturers, contractors, and operators across sectors requiring reliable surface treatment solutions.

Domestic Reach, Supply Assurance & Valued Certifications

Valued in the Indian market for its competitive asking price and exceptional durability, our blasting nozzle is available through rapid packing & dispatch in both individual and bulk formats. With reliable supply ability ensured, each unit complies with industrial norms, meeting standard quality certifications. Our consistently stable market value and trusted domestic reputation make us a preferred supplier for clients demanding certainty and quality.

FAQ's of Blasting Nozzle:

Q: How do I install the blasting nozzle on my equipment?

A: Installation is straightforward with threaded mounting; simply align the 1-1/4" UNC thread and secure the nozzle into your blast hose or tool using appropriate hand tools.Q: What abrasives can be used with this nozzle?

A: Our blasting nozzle supports a wide range of abrasives, including garnet, steel shot, glass bead, aluminum oxide, and others commonly used in industrial applications.Q: When should I replace the blasting nozzle?

A: The nozzle typically offers up to 400 hours of service life depending on the abrasive used. Replacing is recommended if you notice a drop in performance or visible wear.Q: Where is this nozzle primarily used?

A: It is ideal for industrial sandblasting, cleaning, paint removal, rust stripping, and other surface treatment tasks in workshop, manufacturing, and maintenance settings.Q: What are the primary benefits of the tungsten carbide bore material?

A: Tungsten carbide provides high wear resistance, ensuring a longer service life and uniform abrasive flow, even under challenging working conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

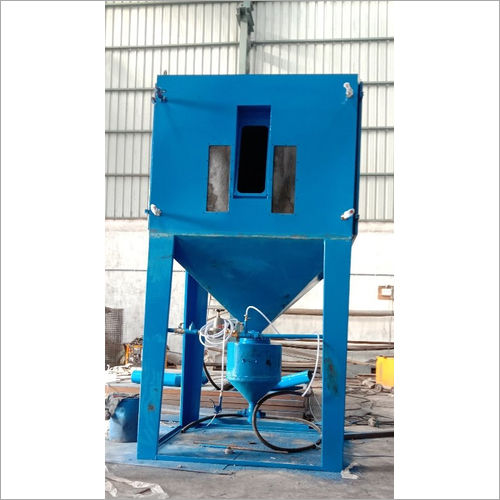

More Products in Blasting Machine Spares Category

Pinch Valve

Price 2800 INR / Pair

Minimum Order Quantity : 1 Pair

General Use : Sand Blasting Machine

Product Type : Pinch Valve

Material : Aluminum Alloy

Color : Blue

BLASTING WHEEL ASSEMBLIES

Price 19500 INR / Number

Minimum Order Quantity : 100

General Use : Blasting machine

Product Type : Air less blasting

Material : Carbon Steel

Blast Control Valve

Price 2100 INR / Pair

Minimum Order Quantity : 1 Pair

General Use : Sand Blasting Machine

Product Type : Blast Control Valve

Material : Stainless Steel Alloy

Color : Silver

Shot Blasting Nozzle Holder Aluminium

Price 450 INR / Pair

Minimum Order Quantity : 1 Pair

General Use : Shot Blasting Machine

Product Type : Shot Blasting Nozzle Holder

Material : Aluminum Alloy

Color : Silver

|

VRAJ ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |