Blasting Machine Spares

Blasting Machine Spares Specification

- Features

- Wear resistant, corrosion protected, easy installation

- Model No

- SBM-SP22

- Production Capacity

- 1000 pcs/month

- Control System

- PLC Controlled

- Operating Temperature

- -10C to 70C

- Drive

- Direct / Belt

- Noise Level

- <80 dB

- Voltage

- 220/380 V

- Machine Type

- Shot Blasting Machine Spare

- Connectivity Options

- Standard machine interface

- Lubricating System

- Automatic/Manual

- Frame Type

- Cast / Welded

- Motor Power

- 2 HP

- Accuracy

- High precision fit

- Frequency

- 50/60 Hz

- Power Rating

- 2 kW - 5 kW

- Cooling System

- Air Cooled

- Product Type

- Blasting Machine Spares

- Technology

- Shot Blasting

- Power Source

- Electric

- Operating Type

- Automatic/Semi-Automatic

- Power

- 2 kW

- Pressure

- 6-8 Bar

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- Custom as per spare type

- Weight (kg)

- Varies with spare; typically 2-15 kg

- Color

- Black / Grey

- Usage & Applications

- Blasting machine maintenance, replacement parts

- Replacement Cycle

- As per machine usage

- Part Category

- Impeller, Blades, Liner, Hub, Rubber Pad

- Compatibility

- Fits standard wheel abrator and shot blasting machines

- Material

- Alloy Steel / Cast Iron

- Lead Time

- 7-10 Days

- Corrosion Resistance

- Yes

- Mounting Type

- Bolt-on / Clamp

- Heat Resistance

- Up to 250°C

- Supplier Type

- OEM / ODM

- Spare Part Certification

- ISO 9001:2015

- Finishing

- Smooth, rust-resistant

- Packaging Type

- Corrugated Box / Wooden Crate

- Service Life

- Up to 800 hours

Blasting Machine Spares Trade Information

- Minimum Order Quantity

- 2 Units

- Main Domestic Market

- All India

About Blasting Machine Spares

Comprehensive Application and Performance Features

Blasting Machine Spares are engineered for effortless installation and compatibility in both classic and advanced shot blasting setups. The application method ensures precise, bolt-on or clamp mounting, while their powder-coated, corrosion-resistant build delivers continued performance under high-pressure, high-temperature conditions. Suitable for maintenance and replacement in OEM and ODM solutions, their area of application spans automotive, foundry, and industrial sectors, guaranteeing seamless functionality thanks to high accuracy and automated lubrication systems.

Sample Availability, Packaging, and Efficient Shipping

Gain market value by accessing sample orders to assess the fit for your domestic manufacturing needs. Each order is securely packed in premium corrugated boxes or sturdy wooden crates, protecting integrity during transit. Express shipping options via major FOB ports in India expedite delivery, further supporting timely project completion. Experience the benefits of smooth procurement and reliable supply to maximize operational uptime and maintain an edge in the domestic and international markets.

FAQ's of Blasting Machine Spares:

Q: How do I select the right Blasting Machine Spare parts for my shot blasting equipment?

A: Identify the specific part category, such as impeller, blades, liner, or hubs, that fits your equipment. Ensure compatibility by referencing your machine's model number, and select parts based on material, dimensions, and mounting type provided in the detailed specifications.Q: What is the typical service life of these Blasting Machine Spares?

A: Under standard operating conditions, these spares offer a service life of up to 800 hours. However, replacement cycles may vary based on usage intensity and maintenance practices.Q: Where are these Blasting Machine Spares primarily used?

A: They are widely used in maintenance and replacement applications within automotive plants, foundries, and various industrial facilities utilizing shot blasting technology for finishing and cleaning operations.Q: What benefits do ISO 9001:2015 certified parts offer?

A: ISO 9001:2015 certification ensures consistent quality, superior performance, and reliability, reducing downtime and enhancing machine efficiency in demanding environments.Q: How are these spares packaged and shipped for domestic and export markets?

A: Parts are carefully packed in corrugated boxes or wooden crates to minimize damage. Express shipping is available via major Indian FOB ports for efficient domestic and international delivery.Q: What is the process for replacing blasting machine spares?

A: Replacement involves safely shutting down the machine, removing worn parts using bolt-on or clamp mechanisms, and installing new certified components, ensuring high precision fit and restoring optimum machine performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blasting Machine Category

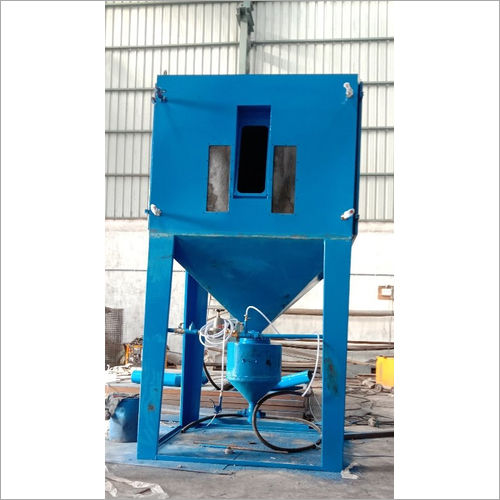

300 KG Sand Blasting Machine

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Operating Type : Semi Automatic

Power Source : Electricity

Product Type : Cleaning Machines

Tumbler Shot Blasting Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Casting

Operating Type : Semi Automatic

Power Source : Electricity

Product Type : Cleaning Machines

Pressure Sand Blasting Machine

Price 1250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Roughness finish

Operating Type : Semi Automatic

Product Type : Other, Sand Blasting Machine

Automatic Pressure Blasting Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Shot Blasting, Shot Pining, sand blasting

Operating Type : Automatic

Power Source : Electricity

Product Type : Other

|

VRAJ ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |